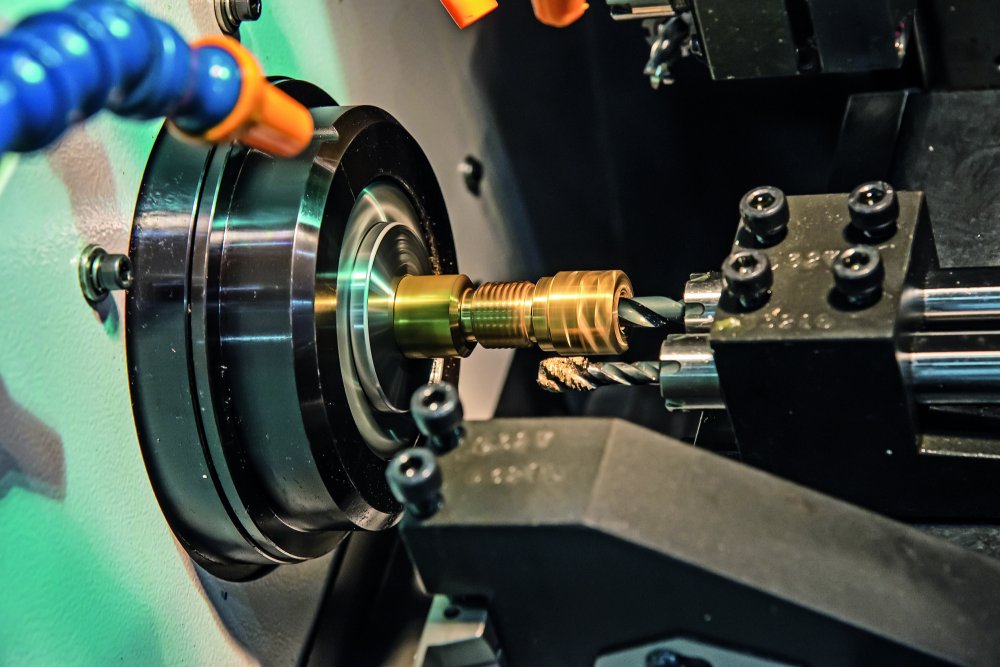

Turning

All materials and dimensions can be pre-mechined on request or according to drawing. Certified dimensional accuracy, high surface quality, special shapes according to drawing (half shells, flange bushings, cone shape and spherical shape), at short notice and flexible.

If you want it done in a hurry:

Whether sawing, turning, milling, drilling, straightening, chamfering or thermal treatments - many things are possible. BEYER Metall is your competent partner for processing and finishing in all common non-ferrous metal alloys. In first-class quality - everything from one source! An overview of the range of products and services in the field of preprocessing/finishing from the companies of the BEYER Group.

Sawing Center

Table belt saws:

up to 1,000 mm material thickness and 3,000 mm cutting length

Pillar band saws:

up to 800 mm material thickness

Plate saws:

up to 250 mm material thickness and 4,000 mm cutting length

Disc saws:

up to 1,500 mm diameter

Thermal Treatment

Thermal tension release

- low stress annealing for all materials possible

- Soft annealing of brass and copper wrought alloys

- Capacity:

width 1,800 mm, height 2,000 mm, length 3,200 mm, weight around 10t - maximum temperature = 650 °C / 1202°F

Contour Cuts

Whether sawn angles or special contours, such as wedge blanks or water jet cut according to drawing. Dimensionally accurate. Everything from one source.

Straightening

All tubes and round bars (round bars up to 77 mm diameter) are straightened.

Do you need finished machined parts?

No problem, get to know our finish machining better.

As a company of the BEYER Group, Brohler Metall and Beyer CNC are powerful partners for finished parts in all common non-ferrous metal alloys. Over 70 years of experience in machining and turning non-ferrous metals combined with advanced production methods guarantee you first-class quality at attractive prices. Together with our competent partners, we offer you the possibility to thermally deburr, anodise or galvanise your products, in addition to the classic processing for your finished parts. The advantage for YOU, everything from ONE hand! And that in best quality, at fair prices.

Turning The turning production area uses state-of-the-art CNC/NC technology to produce turned parts according to DIN ISO 4379 and individual customer drawings. Brohler Metall mainly turns copper alloys, such as bronze (CC493K and CC483K), aluminium bronze (CC333G), brass (CW614N) and many other non-ferrous alloys. At Beyer CNC, on the other hand, the focus is on the wide range of aluminium materials. In addition, components made of brass (CW614N), grey cast iron (GG/GGG) and various types of steel/stainless steel can of course also be supplied. NC and CNC machining up to ø 800 mm. Conventional processing over ø 2,000 mm.

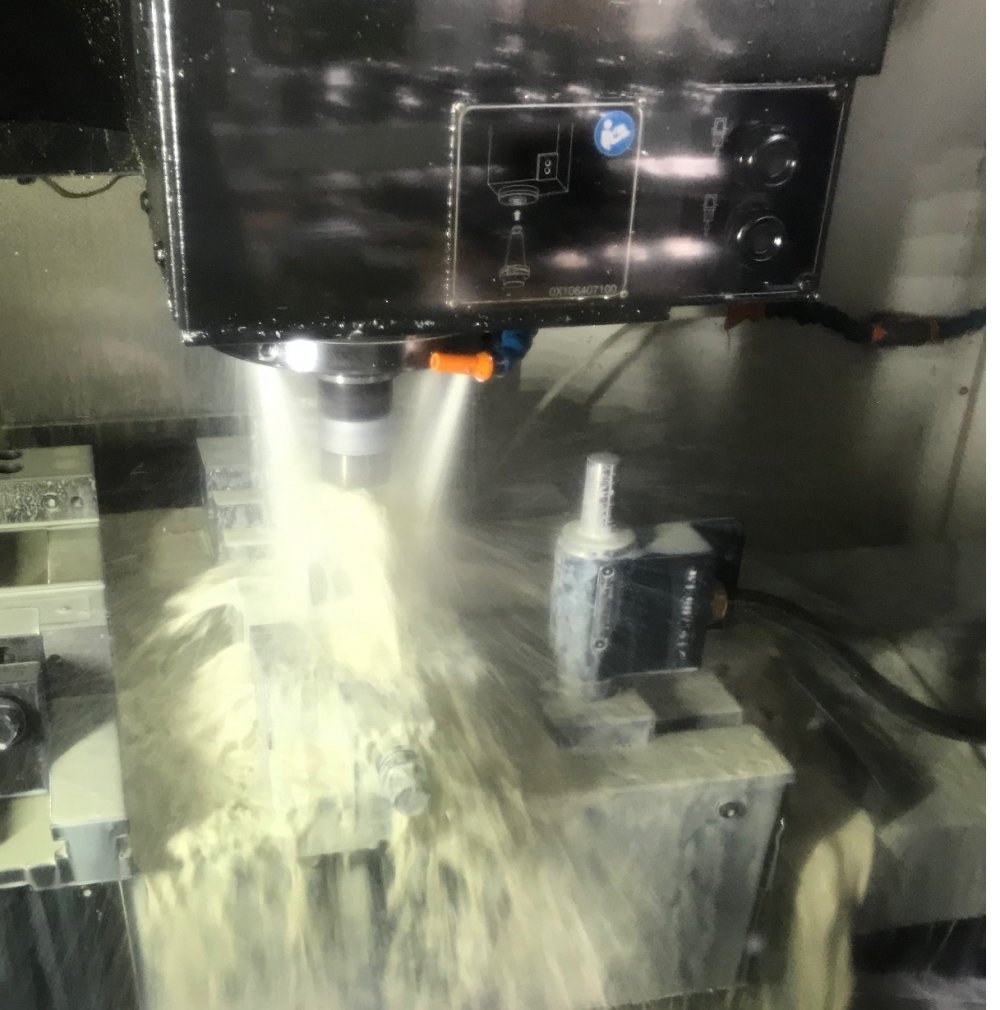

Milling

Beyer CNC mainly mills aluminium alloys and other non-ferrous metals, as well as FE metals.

Milling of X 3,000 mm x Y 800 mm x Z 800 mm.

Using various vertical machining centres of the Mazak brand: Traverse path From: X=1,050, Y=530, Z=510 To: X=1,740, Y=760, Z=660

as well as horizontal machining centres of the Mori Seiki brand: Traverse path 2 pallets 400x400

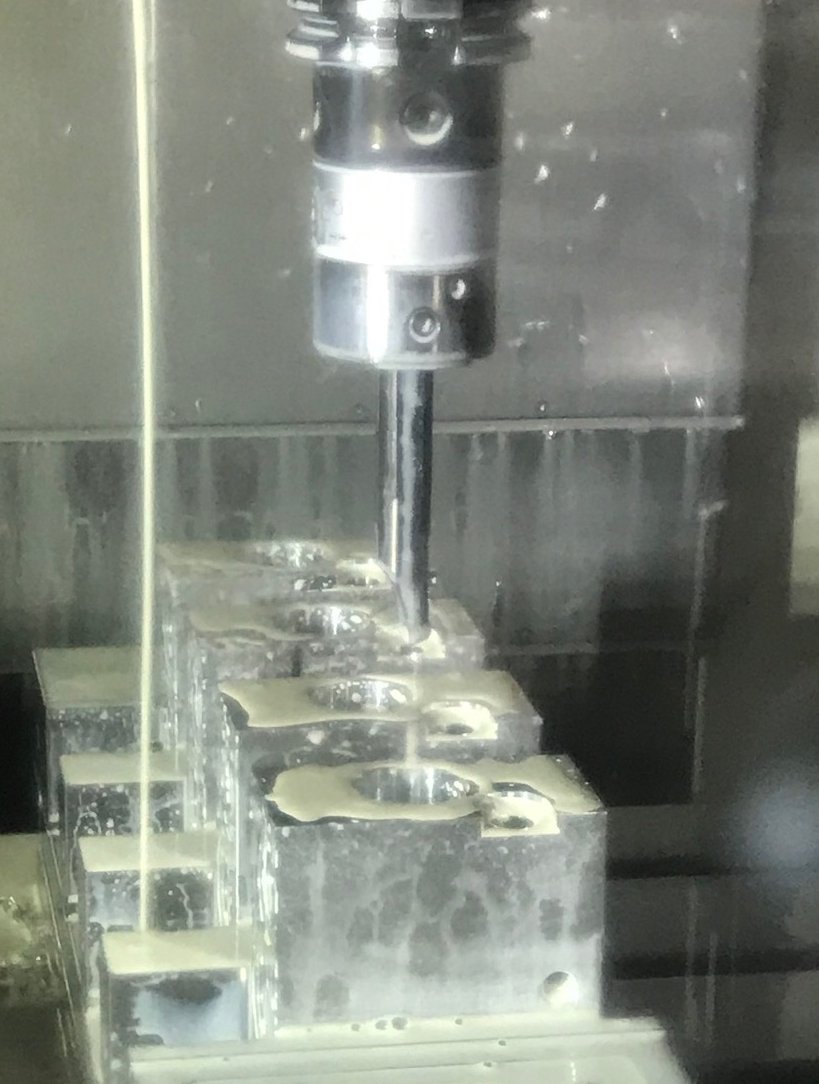

Tapping

Beyer CNC specialises in the manufacture of hydraulic, valve and control blocks, as well as adapters. You can choose from all common aluminium materials, including of course the more modern, RoHS-compliant, lead-free grades. These components are also available in grey cast iron or steel. For the technical challenges of various valve manufacturers we have a very large selection of cavity forming tools at our disposal. In total, the Beyer CNC can call on more than 800 different tools (forming tools, drills, milling cutters, etc.), starting from a size of 1 mm diameter.

We look forward to your inquiry!

You can also benefit from the products of Brohler Metall

Bearing In addition to rolling bearings, plain bearings are the most commonly used bearing designs in mechanical and equipment engineering. When components move relative to each other, plain bearings should guide them with little friction as possible, wear-free and with the greatest possible accuracy. The fact that plain bearings can also be produced in split design considerably simplifies mounting and dismounting for the user.

Guide bearings CNC milled parts made of copper alloys are typically used as guide rails in general mechanical engineering due to their special properties.

Solid lubricant bearings and guide rails, maintenance free and safe ... (MaFeBro Maintenance-Free Bronze) With MaFeBro you get maintenance-free bronze bearings and guide rails. These are products in different bronze alloys with dot-shaped embedded graphite inserts.

Dry sliding bearings according to DIN ISO 3547-2 (DIN 1494) Dry sliding bearings according to DIN ISO 3547-2 consist of a tin-plated steel back with sintered bronze and PTFE-coated sliding surface. They are intended for use in rotary and longitudinal movements. Dry sliding bearings are characterised by a low coefficient of friction, good sliding properties and low wear.

Sintered bronze bearings Sintered bronze bearings are a variant of sliding bearings made of porous bronze and are self-lubricating and largely maintenance-free due to subsequent oil impregnation. Sintered metals are produced by pressing metal powder under high pressure. The advantage over solid plain bearings is that sintered metal has open pores, so that these pores fill with lubricants (for example oils).

Convince yourself of our efficiency "Made in Germany".

We will be pleased to calculate your requirements.

Get in contact with us.

For turned parts: info@brohler-metall.de or www.brohler-metall.de

For tapping and milling parts: info@beyer-cnc.de